AM Process Categories

The 7 official AM process categories according to ASTM

A common way to classify technologies is by the 7 main categories defined by ISO and ASTM in the standard 52900-15. We will briefly give an overview of the 7 categories including process description, material categories, typical applications and AM process variants, followed by videos of some of the most common AM processes below.

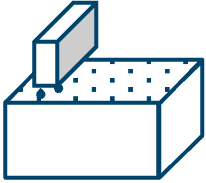

Process description:

A liquid bonding agent is selectively deposited to join powder materials.

Materials:

Metal and sand

Typical applications:

- Serial metal parts ≈500-20.000

- Printing of sand molds

AM process variants – a selected overview

- Binder Jetting (BJT)

- Multi Jet Fusion© (MJF)

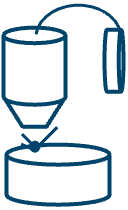

Process description:

A focused energy source used to fuse materials as they are being deposited.

Materials:

Metal

Typical applications:

- Repair/coating of shafts for oil & gas/heavy duty machinery

- Aviation Ti parts

AM process variants – a selected overview

- Laser Engineering Net Shape (LENS)

- Electron Beam Additive Manufacturing (EBAM)

- Rapid Plasma Deposition

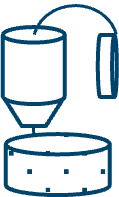

Process description:

Material is selectively dispensed through a nozzle or orifice.

Materials:

Metal, polymer and composite

Typical applications:

- 3D printing @ home

- High performance polymers (e.g. PEEK)

AM process variants – a selected overview

- Fused Deposition Modeling (FDM) – Polymer

- Arburg Plastic Freeforming (APF) – Polymer

Process description:

Droplets of build material are selectively deposited.

Materials:

Metal, polymer and wax

Typical applications:

- Multicolor/-mate-rial prototypes

- Wax patterns for jewelry

- Molds for investmment casting

AM process variants – a selected overview

- Material Jetting (MJ) – Polymer

- Multi-Jet Modeling (MJM) (also: MultiJet Printing (MJP), PolyJet) – Polymer

- NanoParticle Jetting (NPJ) – Polymer

Process description:

Energy source selectively fuses regions of a powder bed.

Materials:

Metal and polymer

Typical applications:

- Polyamer prototypes

- Complex metal parts: Implants, fuel nozzle, turbine blades

AM process variants – a selected overview

- Laser-beam PBF of polymers (L-PBF) (also: Selective Laser Sintering (SLS)) – Polymer

- LB-PBF of metals (L-PBF) (also: Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), Laser Metal Fusion (LMF)) – Metal

- Electron beam PBF of metals (E-PBF) (also: Electron Beam Melting (EBM)) – Metal

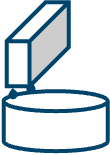

Process description:

Sheets of material are bonded to form a part.

Materials:

Composite, paper

Typical applications:

Full color paper prototypes

AM process variants – a selected overview

- Laminated Object Manufacturing

(LOM) – Other

Process description:

Liquid photopolymer in a vat is selectively cured by light-activated polymerization.

Materials:

Ceramic, photopolymer

Typical applications:

- Silicone hearing aids

- High surface finish prototypes

AM process variants – a selected overview

- Stereolithography (SLA) – Polymer

- Digital Light Processing (DLP) – Polymer

- Continuous Digital Light Processing (CLIP) – Polymer

- Lithography-based Ceramic – Ceramic Manufacturing (LCM) – Ceramic

Videos of selected processes

Additive Manufacturing technologies in action

Below you can find a video explaining the 7 different process categories as well as brief videos of some of the most common Additive Manufacturing processes by hubs. A more detailed explanation of the different processes can be found in the two online learning programs Polymer Technologies and Metal Technologies.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: CanalDivulgación

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: hubs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: hubs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: hubs

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSource: Thomáš Vít

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationRead more about this topic in the AM Fundamentals Course.