Metal Material Extrusion

Low batch metal printing

The Metal Material Extrusion (ME) process is based on the widely known polymer technology most widely known as Fused Deposition Modeling, or FDM. Several variants are known and many new suppliers are currently going to market with either metal ME system technology or feedstock.

Technology principle

How does Metal Material Extrusion work?

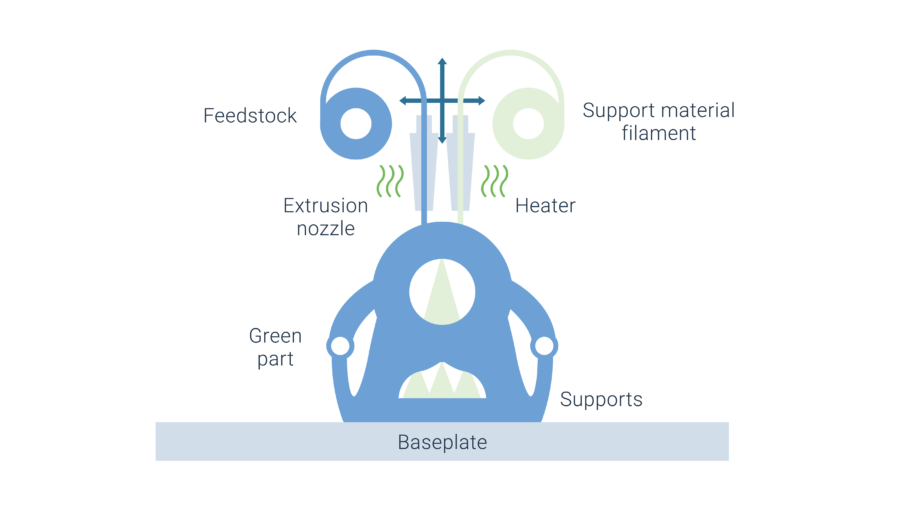

Metal Material Extrusion (ME) is a technology based on the widely known polymer ME process. The feedstock in form of a filament, a rod or MIM granulate is made out of a compound of polymer binder and metal powder. It is processed through a printhead which is moving in xy-direction while the build platform is being moved in z-direction. The polymer component of the feedstock is melted and deposited layer by layer on the build platform until the part is completed. The resulting green body is then post-processed by removal of the polymer binder phase and subsequent sintering. During sintering near melting temperature densification leads to the final metal part.

So far, most machine vendors mainly focus on developing and providing systems for 3D printing. For the post-processing debinding and sintering systems from MIM industry are used. However, some players recently developed specific solutions for debinding stations and furnaces to offer a complete process chain.

Metal ME with filament

The first variant of the Metal ME technology makes use of a filament as a feedstock. The filament is produced by extrusion of a compound of metal powder and binder and has a diameter of few millimeters. It can be purchased on spools. The binder content is usually around 50 vol.-% and consists of different components depending on the debinding process. For solvent based debinding processes one component is a first level wax-based binder that is removed by immersing the green part in a solvent. The other component is a second level thermoplastic binder that is removed in the sintering process.

During sintering a linear shrinkage of 18 to 20 % in all dimensions occurs. This volume change has to be considered when designing the part and poses the largest challenge in fast and wide-spread industrial adapting of the process. To improve the surface quality, green parts can be machined prior to sintering. This greatly reduces the effort compared to processing sintered parts.

Metal ME with rods

The rod-based Metal FDM process is a proprietary technology of the company DESKTOP METAL. It is similar to the filament-based process, however, a rod-shaped material is used as a feedstock. The material is extruded from a cartridge. A selection of well-studied metals from MIM industry is available as raw materials.

Compared to Metal FDM filaments, the rods contain a higher percentage of metal due to the fact that they need to be less elasticity not being wrapped on a spool.

Metal ME with MIM granulate

In a third variant Metal Injection Molding (MIM) granulate is used as feedstock. The machine system is different from those used for Metal ME with filament or rods. Similar to the plastifying unit of an injection molding machine the MIM granulate is molten and compounded in a screw extruder. Due to the high pressure that is built up, ME machines for MIM granulate have a higher throughput. This results in a higher building speed.

A further advantage is that standard materials from MIM industry are used and therefore a wide range of possible choices are already widely available. These are low-priced and have already known processing routes for debinding and sintering.

Read more about this topic in the Metal Technologies Course.