Metal AM Technologies

Constant development of new processes

The number of metal AM processes has increased since the late 90s and today there is a wide range of metal technologies that are used in an industrial context. It is therefore hard to keep an overview of all the different metal processes and companies, and there seems to be a new process (or a company claiming to offer a new process) almost every week.

Technologies included in the AMPOWER Academy

Focus on the most mature metal technologies

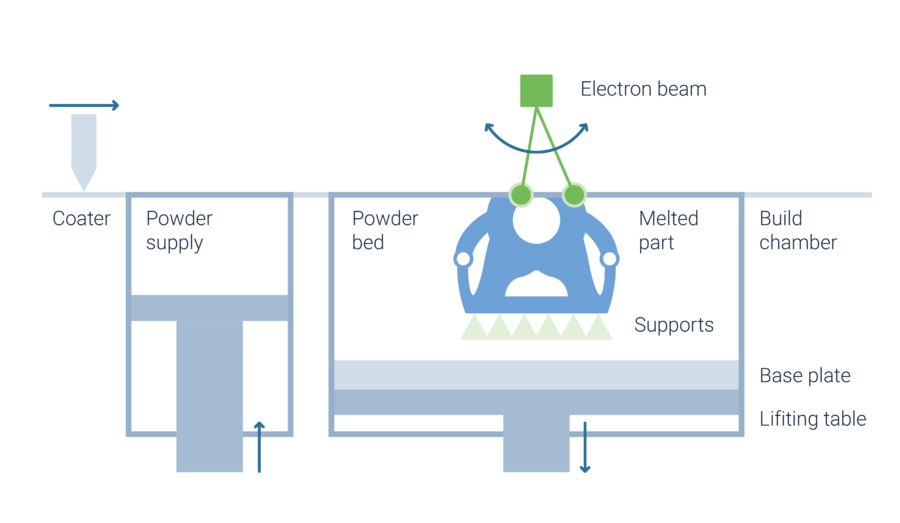

The main benefits of L-PBF technology are the good mechanical properties of the resulting parts, their high density and the fine resolution. The technology is well-established with a large variety of available metal alloys. It is a single-stage production that enables a high freedom of design. Scrap material is reduced through near net shape production and recycling of the unmelted powder.

However, internal residual stresses that are induced during cooling constitute a restriction since they can lead to part deformations or cracks. Support structures to counteract such stresses have to be removed after the building process. The relatively rough surface, moreover, typically requires several post-processing steps. The investment costs for machine systems as well as the feedstock material are considerably high and may pose a limiting factor on potential business cases.

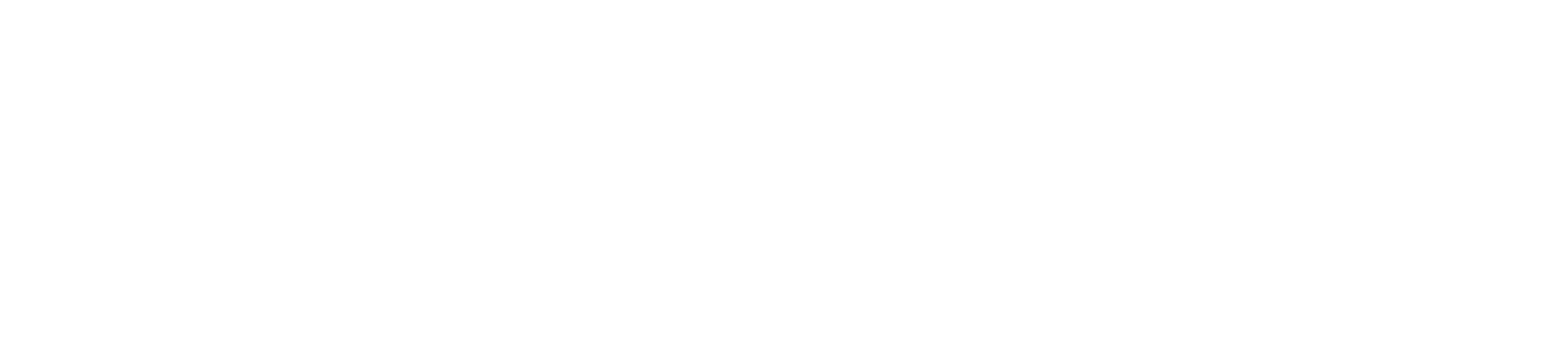

The high density and good mechanical properties of parts manufactured via E-PBF are the main advantages. The possibility of stacking parts in the built chamber enables the production of bigger lot sizes and makes production more efficient. E-PBF is a single-stage production. A recycling of the unexposed powder is possible, however, due to formation of the powder cake, a more extensive treatment of the powder is necessary. As a result of preheating the powder bed, low temperature gradients occur during the process, and only minor internal stresses develop.

Restrictions are mainly the low degree of dissemination of the technology and the small selection of available qualified alloys. The freedom of design is limited due to formation of the powder cake that is difficult to remove from channels and internal structures.

In classical BJT systems such as the ones distributed by EXONE or DIGITAL METAL the liquid binding agent is selectively deposited with a single print head. Meaning the width of the print head does not cover the full width of the powder bed. Therefore, the print head moves multiple times in xy-direction over the powder bed to completely cover the printing area and distributing the polymer binder.

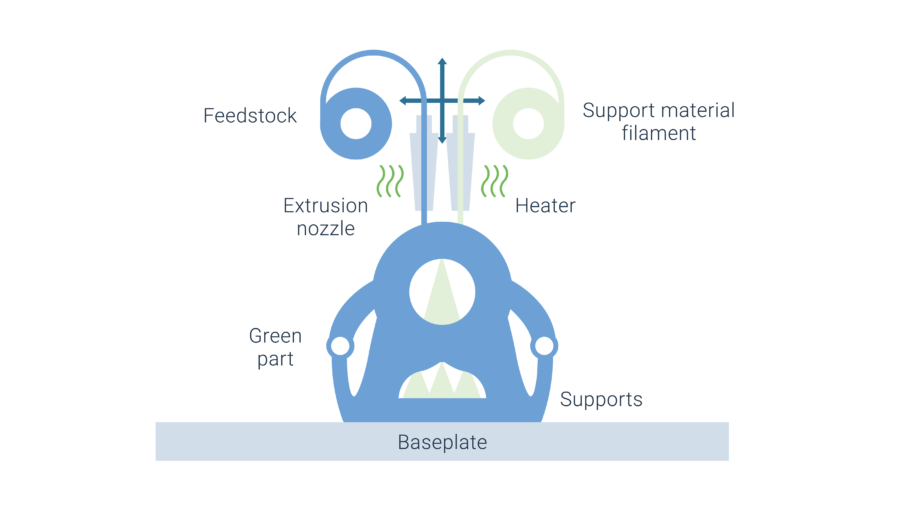

BJT is a sinter-based Additive Manufacturing technology which means, the parts are printed as green parts with a certain polymer binder saturation. After printing, parts have to be debinded and sintered mostly in furnaces.

So far, most machine vendors mainly focus on developing and providing systems for the actual printing of the green parts. For the post-processing debinding and sintering systems from MIM industry are used. However, some players recently developed specific solutions for debinding stations and furnaces to offer a complete process chain.

Read more about this topic in the Metal Technologies Course.