Applications of metal L-PBF

Applications of L-PBF

L-PBF with applications across all industries

Laser Powder Bed Fusion (L-PBF) is the most industrialized metal AM technology today. After early adopters within the medical and aerospace industry have proven the suitability of L-PBF for end use parts, companies across all industries have identified further cases in recent years.

L-PBF can be used to produce complex geometries ranging from several millimetres to dimensions close to 1m. Recent advancements in productivity and the increasing automation of subsequent process steps make L-PBF more and more suitable for applications in higher volumes. The technology therefore has a wide range of applications, including prototypes, end-use components, toolings and spare parts.

What you will find in this section

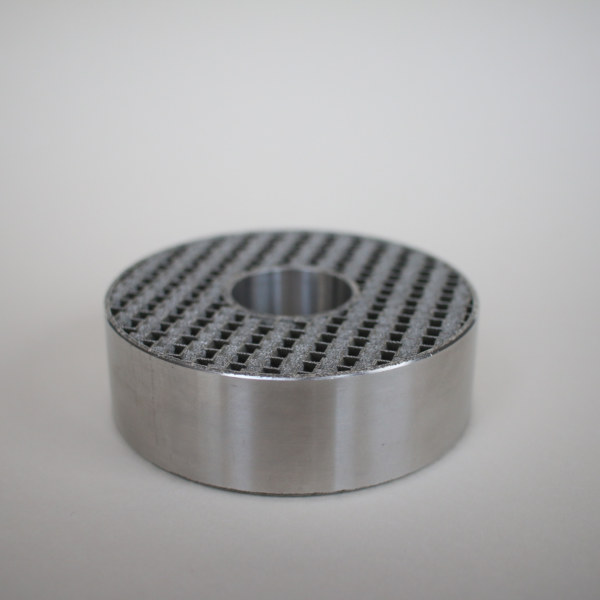

Catalytic reactors

Air purification component. 3D printing gives the free form design possibilities to fully optimize the structure of a catalytic reactor, going beyond designs made with traditional processes. This enables AddCat to improve the catalytic process making the air purification more efficient and reliable in a smaller reactor volume. Courtesy of AddCat

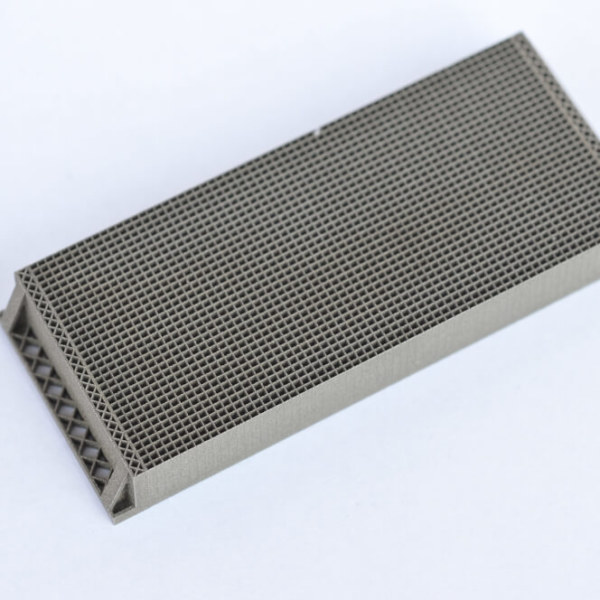

Anti-scatter grid

The anti-scatter grid (ASG), made out of pure tungsten, is placed on top of CT detectors to enhance image quality by rejecting scattered radiation. Through additive manufacturing, it is possible to 3D print 100 micron thick walls at a positional accuracy of 25 microns. Ability to print highly accurate and thin walls (100 microns). Courtesy of Dunlee

ARNO Cutting Tool

Cutting tool innovation by ARNO and Rosswag with patented coolant supply design manufactured in serial production. The additive manufactured grooving tool delivers coolant directly to the cutting zone of the insert and underneath the tool flank for highly efficient parting off, grooving and groove turning. This leads to financial and technical benefits due to an increased tool life of the insert and a higher process security. Courtesy of Rosswag GmbH.

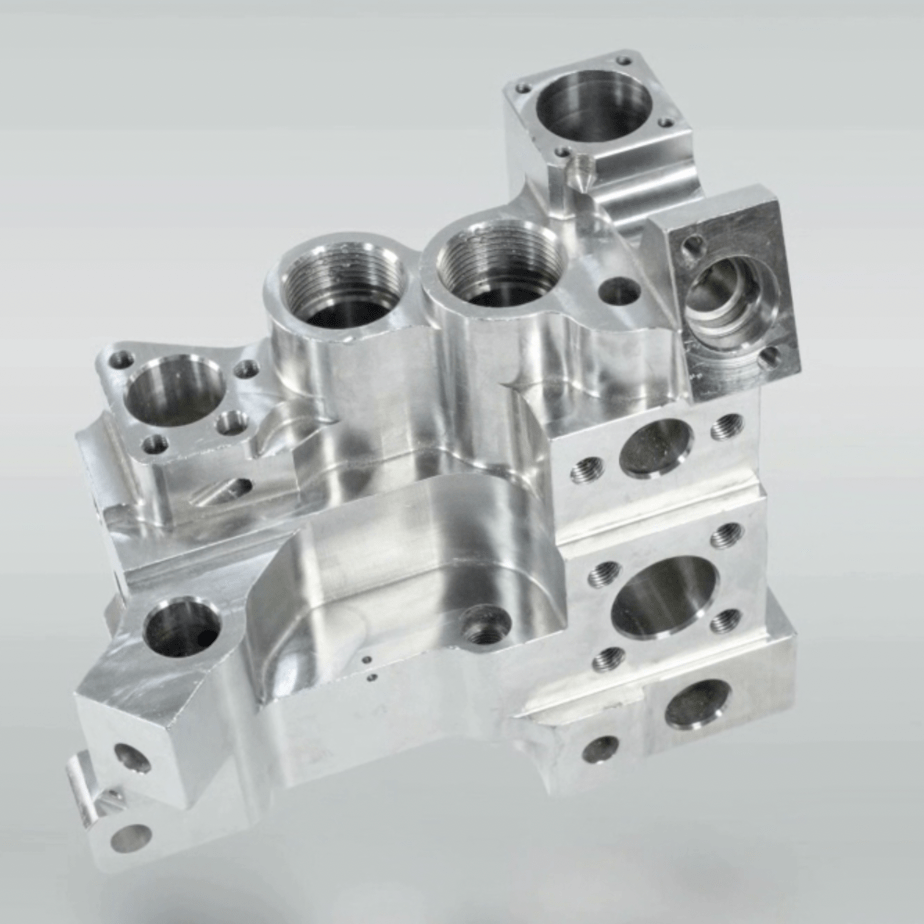

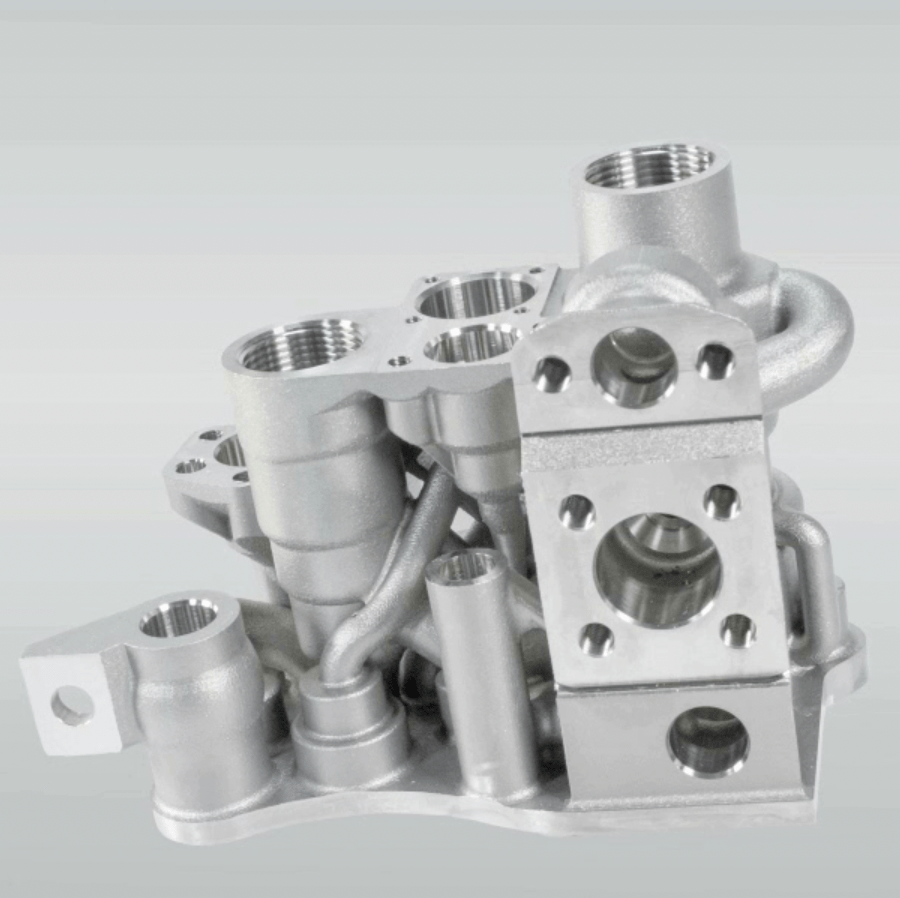

Hydraulic valve block

Old vs. new design

User

Airbus

Industry

Aviation

Material

Stainless Steel

Technology

Laser Powder Bed Fusion

Classification

Qualified end part

The objective was to replace a conventionally manufactured high-pressure hydraulic valve block with an additively manufactured one. The component is produced by LIEBHERR AEROSPACE and used on an AIRBUS A380.

The primary flight control component moves the spoiler of an aircraft to the desired position during take-off and landing and must thus meet highest quality standards.

The original component is machined from a forged block with several drillings and assembly operations. This leads to limited design freedom and long lead times.

Autoclave for High Pressure Applications

The autoclave with integrated tempering channels is certified according to the European Pressure Equipment Directive (2014/68/EU) Category III. It has an operating pressure of 225 bar. The autoclave features a more than two meter long interior channel for tempering fluid which winds around the container wall. The AM design enables faster temperature cycles, better regulation of an even temperature distribution as well as optimized tempering of the component. The component is produced with L-PBF from stainless steel alloy. Courtesy of BASF SE.

Energy feedthrough

The part transmits and distributes compressed air. Advantage by Additive Manufacturing through economic substitution of costly extrusion press part. Images courtesy of Festo AG & Co. KG