How much does Additive Manufacturing cost?

Additive Manufacturing cost

How much does Additive Manufacturing cost?

If during the evaluation and decision process Additive Manufacturing technology cannot show its cost-effectiveness or increase the margin, other means of production will be employed. Thus, it is critical to understand how to derive Additive Manufacturing cost on component level.

What you will find in this section

Course structure

What will be covered in this course

This online learning course is broken down into several sections.

- The section Cost along the process Chain goes through the different steps of the chain and discusses it in more detail for different metal technologies.

- The section Cost Calculation Applied gives some rules of thumb to quickly estimate cost per part and discusses two sample applications.

- The section Service Supplier Cost Analysis gives an overview of the service supplier landscape and their cost level.

- The section AMPOWER Cost tool describes the cost calculator developed by AMPOWER

Cost drivers along the manufacturing chain

From data preparation to finished component

Data source: Additive Manufacturing – next generation (AMnx) Study by Roland Berger April 2016

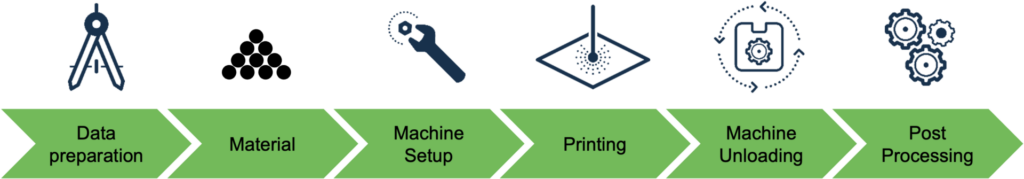

The AM process chain

Data preparation is typically a one-time cost incurred when a part is printed for the first time. For serial production, this cost is distributed across the batch, making the cost per part negligible. However, in prototyping and low-volume production, where only a small number of parts are produced, data preparation can constitute a significant portion of the overall manufacturing cost.

Key steps in data preparation include:

- Part orientation: Optimizing the orientation to minimize support material, reduce build time, and improve surface quality.

- Support structure design: Necessary for certain geometries to prevent deformation or failure during the build process, particularly for overhangs in metal AM.

- File conversion and slicing: Converting CAD designs into a format compatible with the AM machine and slicing the geometry into layers for printing.

Material costs in metal AM include the raw material and unavoidable material losses:

- Powder-based processes such as Powder Bed Fusion (PBF) or Directed Energy Deposition (DED) can result in significant powder waste due to overspray or residual material.

- Material losses may also occur during sieving and recycling to maintain powder quality, with some powders degrading after multiple uses.

- Metal feedstock, such as titanium, Inconel, or stainless steel powders, tends to be costly, but a lower material usage compared to conventional manufacturing processes often equalize the expenses.

The cost of part production in metal AM is affected by:

System Investment:

- Investment cost into metal AM machines typically range from €100,000 to over €1.5 million, depending on the technology and requirements.

- Maintenance, calibration, and consumable parts add to operational costs.

Productivity:

- Build rates for metal AM are generally slower than those for polymer AM, heavily influenced by layer thickness, deposition rates, and energy source efficiency (e.g., lasers or electron beams).

- Optimizing build parameters for speed and part quality is critical to reducing costs.

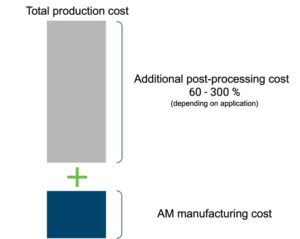

Post-processing is a mandatory step for nearly all metal AM parts, often accounting for a significant share of the overall cost. It includes:

- Support removal: For parts with intricate geometries or substantial overhangs.

- Surface finishing: Achieving the desired surface roughness through machining, grinding, or bead blasting.

- Heat treatment: Processes such as stress relief, annealing, or Hot Isostatic Pressing (HIP) improve mechanical properties and remove residual stresses.

- Inspection and testing: High-value parts, especially in industries like aerospace and medical, undergo rigorous non-destructive testing (e.g., X-ray, CT, or ultrasonic testing).

Qualification costs for metal AM are industry-dependent and can vary significantly:

- Aerospace and medical sectors demand stringent material testing, part certification, and regulatory compliance. Qualification expenses can range from €50,000 to over €500,000 per project, depending on complexity and standards.

- Even in less regulated industries, thorough documentation, repeatability, and reliability testing are essential to ensure consistent production quality.

Metal AM often leads to indirect cost savings that are critical for assessing its overall value:

- Design for AM (DfAM): Enables the production of lightweight and highly complex geometries that reduce material use and assembly requirements.

- On-demand manufacturing: Minimizes inventory and storage costs by enabling localized or just-in-time production of spare parts.

- Performance optimization: Metal AM parts designed for weight reduction or enhanced functionality can improve performance, particularly in aerospace and automotive applications.

- Reduced tooling costs: Metal AM eliminates or reduces the need for molds and dies, making it ideal for low-volume production or high-value prototyping.

Influencing factors for each step

- Time for data preparation

- Labor cost rate

- Total number of parts

- Software costs

- Part volume

- Material density

- Material cost

- Material losses

- Time for machine preparation

- Labor cost rate

- Machine hourly rate

- Machine hourly rate

- Printing time

- Consumables

- Machine hourly rate

- Labor cost rate

- Unloading time per batch

- Support removal

- Heat treatment

- Sintering (When required)

- Finishing operations