Polymer Technology Landscape

Polymer technology landscape

What are common polymer technologies?

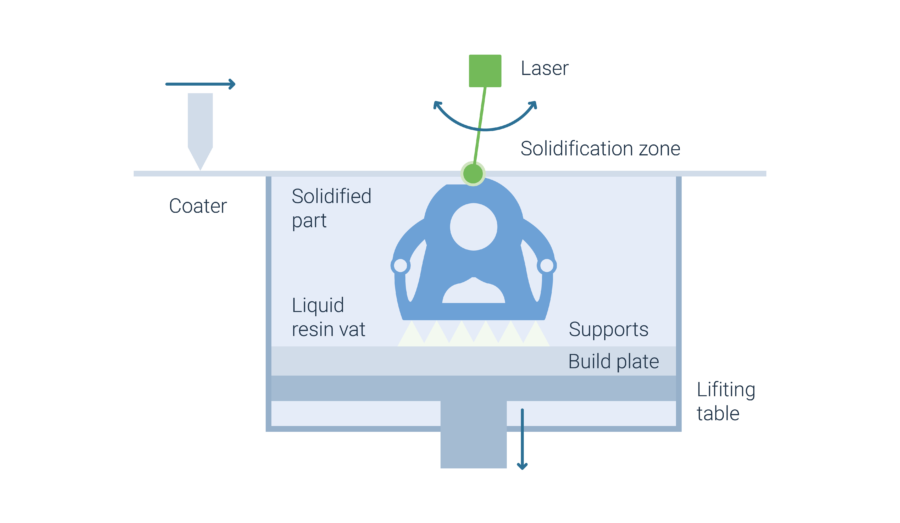

The development of the Additive Manufacturing landscape dates back to the early 80s and started with the invention of the Stereolithography process by Charles Hull. This Invention can be declared as the point of origin for the polymer AM market as well as the entire AM market. It paved the way for early adopters of the technology and the development of further technologies principles. Since then the number of processes and companies has exploded, making it hard to keep an overview.

What you will find in this section

Course structure

What will be included in this course

The goal of this course is to provide an overview of the most mature polymer Additive Manufacturing processes. In the next section, we will thus discuss the maturity of polymer technologies and discuss the current status of established and upcoming technologies.

In the following sections we collected important information for the most mature processes, including functional principle, technical and economic characteristics as well as application examples.

After that you will find a comparison between the different process categories that can help you identify the right technology for your application.

Technology Focus

Focus on the most mature polymer technologies

In the AMPOWER Academy we will focus on the following technologies:

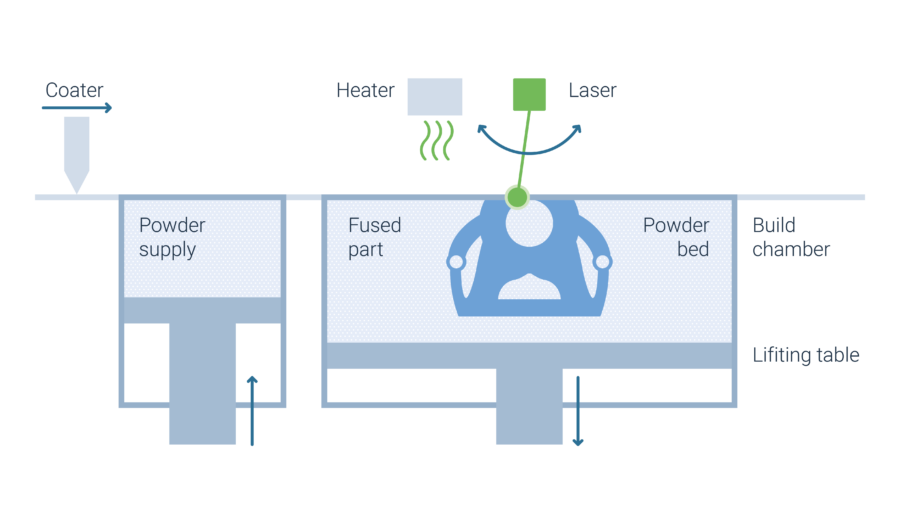

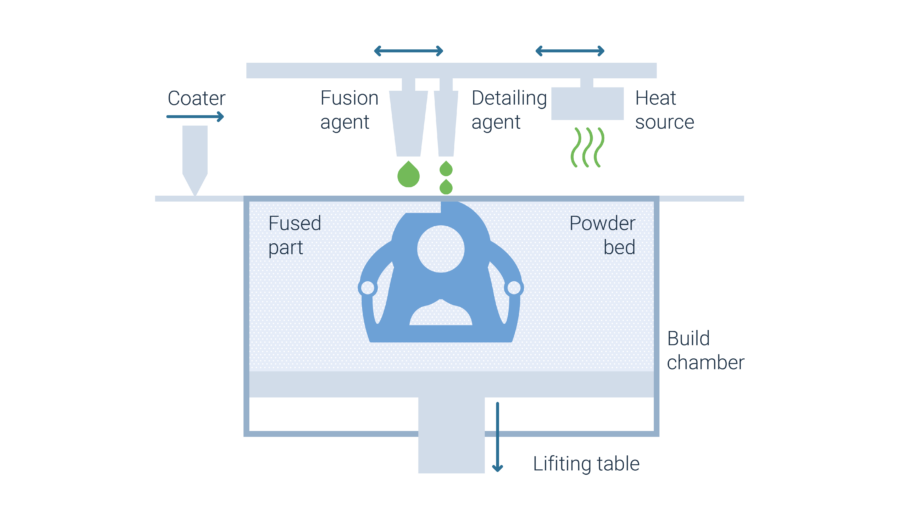

We will cover two sub-categories of the Powder Bed Fusion Family: Laser Powder Bed Fusion and Thermal Powder Bed Fusion.

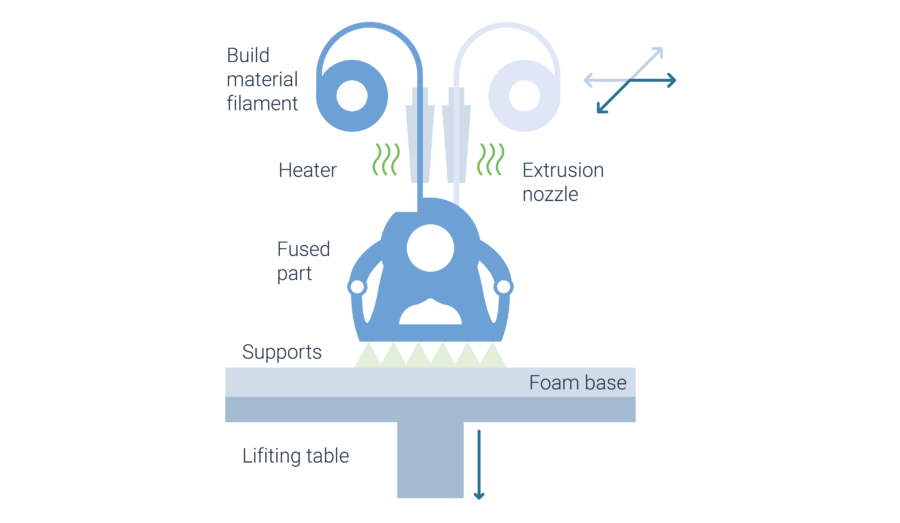

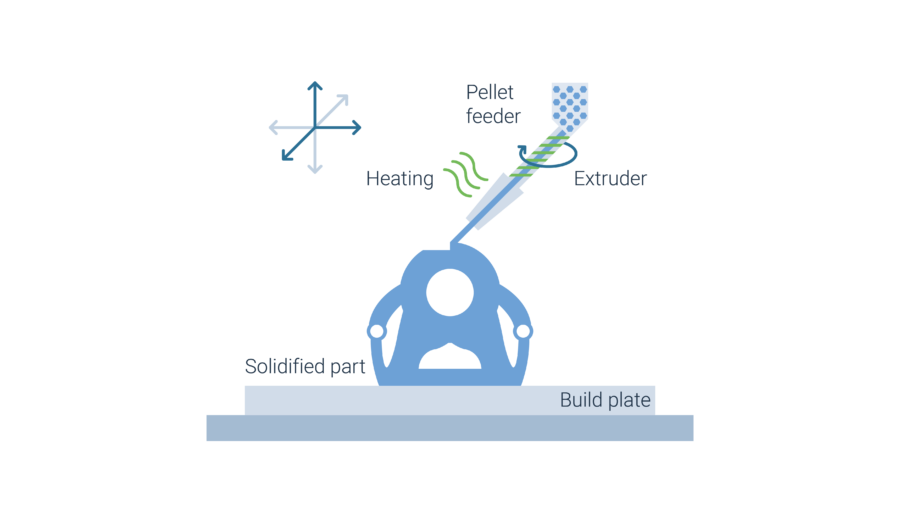

We will cover two sub-categories of Material Extrusion (ME): Filament Material Extrusion and Pellet Material Extrusion.

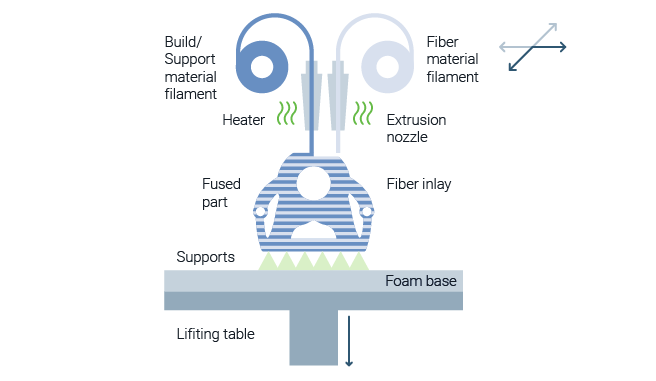

Continuous Fiber Material Extrusion is an advanced form of Filament-Based Material Extrusion that incorporates continuous fibers to enhance mechanical properties. Offered by suppliers like MARKFORGED, ANISOPRINT, and DESKTOP METAL, the process involves heating thermoplastic filament and extruding it through a nozzle while embedding continuous fibers selectively to strengthen heavily loaded areas of the part.

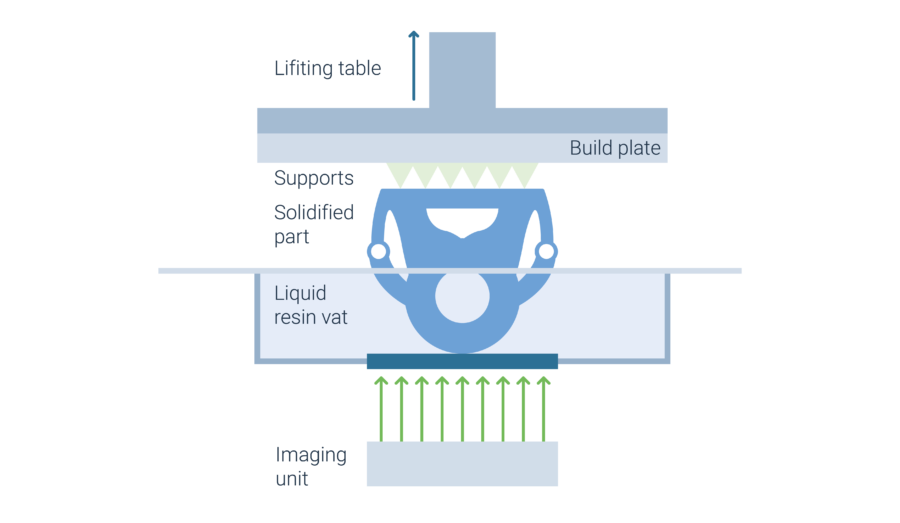

We will cover two sub-categories of Vat Polymerization: The original Vat Polymerization process, also known as Stereolithography (SLA), as well as Area-wise Vat Polymerization.

Nowadays this process is especially popular in the medial sector. Dental aligners, hearing aids and other customized products are produced via this technology in high numbers and take advantage of the accuracy and speed of this technology.

Polymer technology map

Overview of polymer technologies and machine OEMs

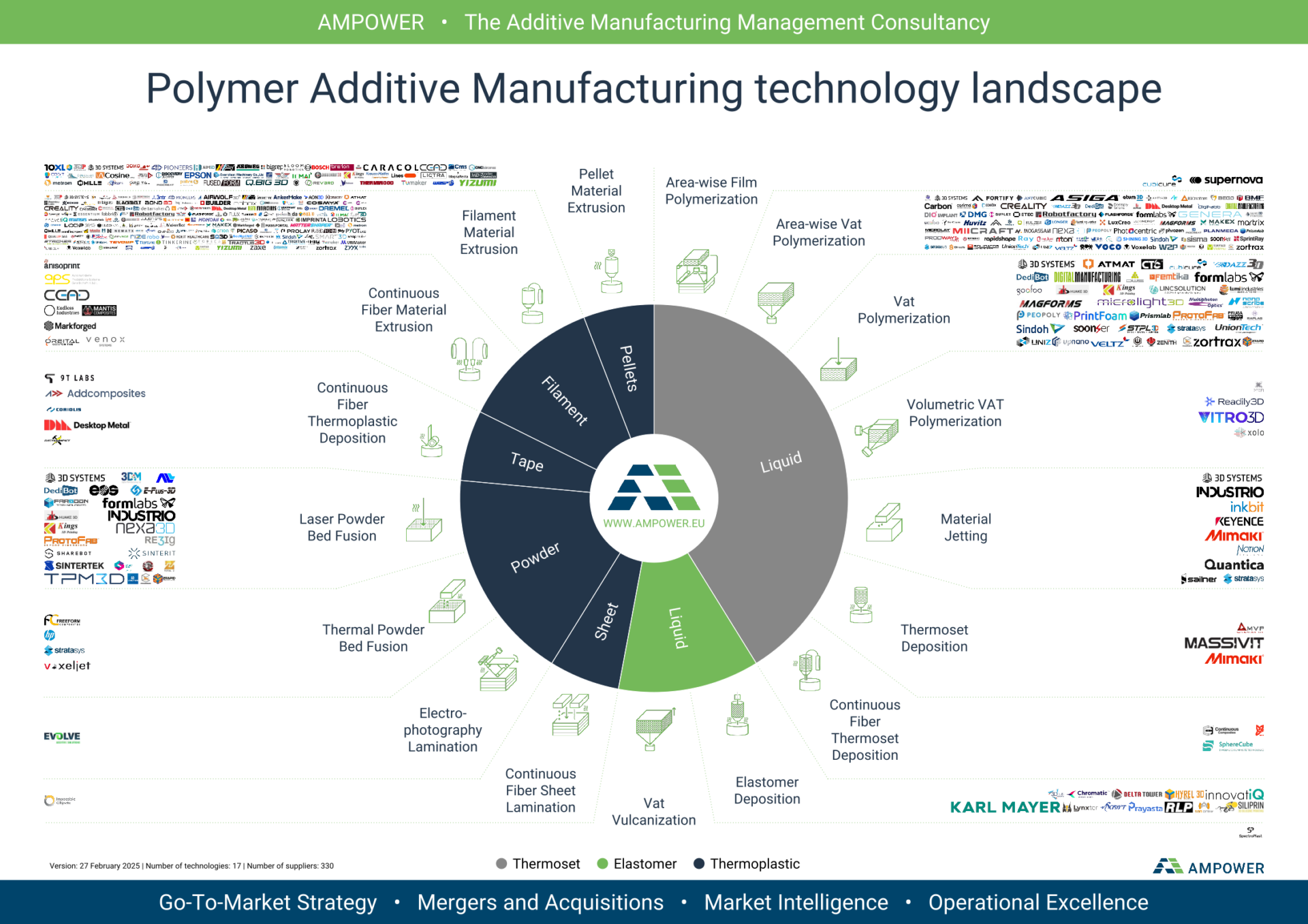

The graphic above provides an overview of the current polymer AM technology landscape and machine OEMs.

As of February 2025, 17 different working principles are known with 330 OEMs supplying machines. The map shows that out of 17 sub processes, 9 work with a liquid feedstock. VAT Polymerization and Filament Extrusion are the two leading technologies in terms of number of suppliers.