NIKON Hiroyuki Nagasaka

“The newly designed training program which has been developed by AMPOWER, will provide engineers with the necessary knowledge, skills, and

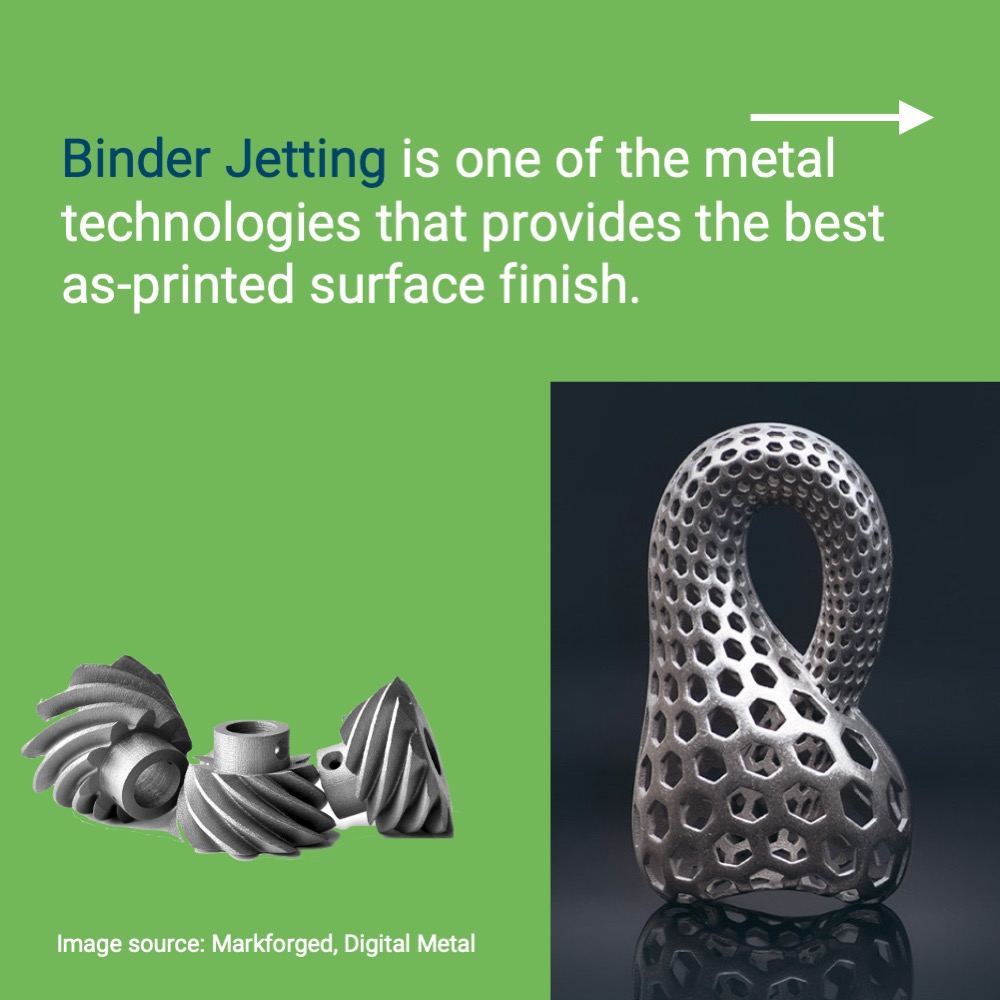

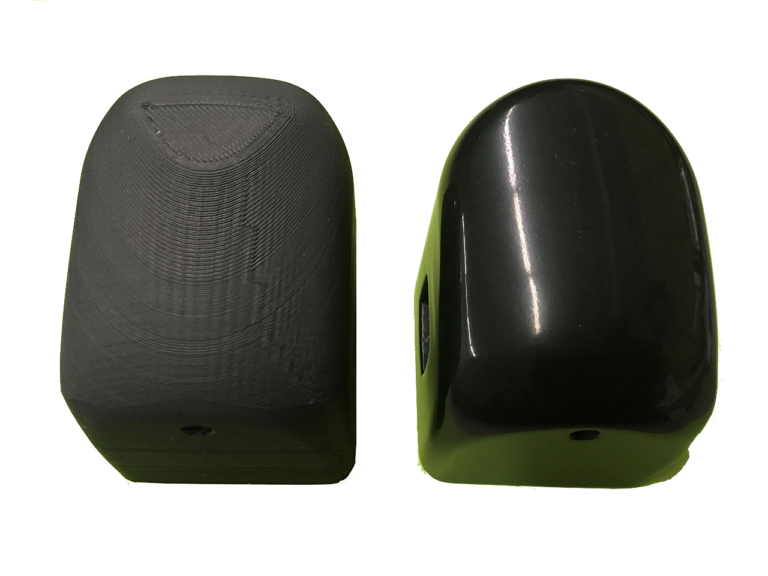

While 3D printing has revolutionized many aspects of manufacturing, one of its ongoing challenges is achieving high-quality surface finishes, especially for industrial applications. Parts produced using technologies like Laser Powder Bed Fusion (L-PBF), Binder Jetting (BJT), and Material Extrusion (ME) often exhibit rough finishes, which can limit their use in applications requiring precision and smoothness.

This article explores the current challenges, advanced solutions, and practical tips for improving the surface quality of 3D-printed parts.

Many 3D printing technologies inherently produce rough surfaces, particularly those based on powder or wire processes. For example:

Polymer processes like Laser Powder Bed Fusion and Material Extrusion struggle to match the smooth finishes of conventional methods like injection molding.

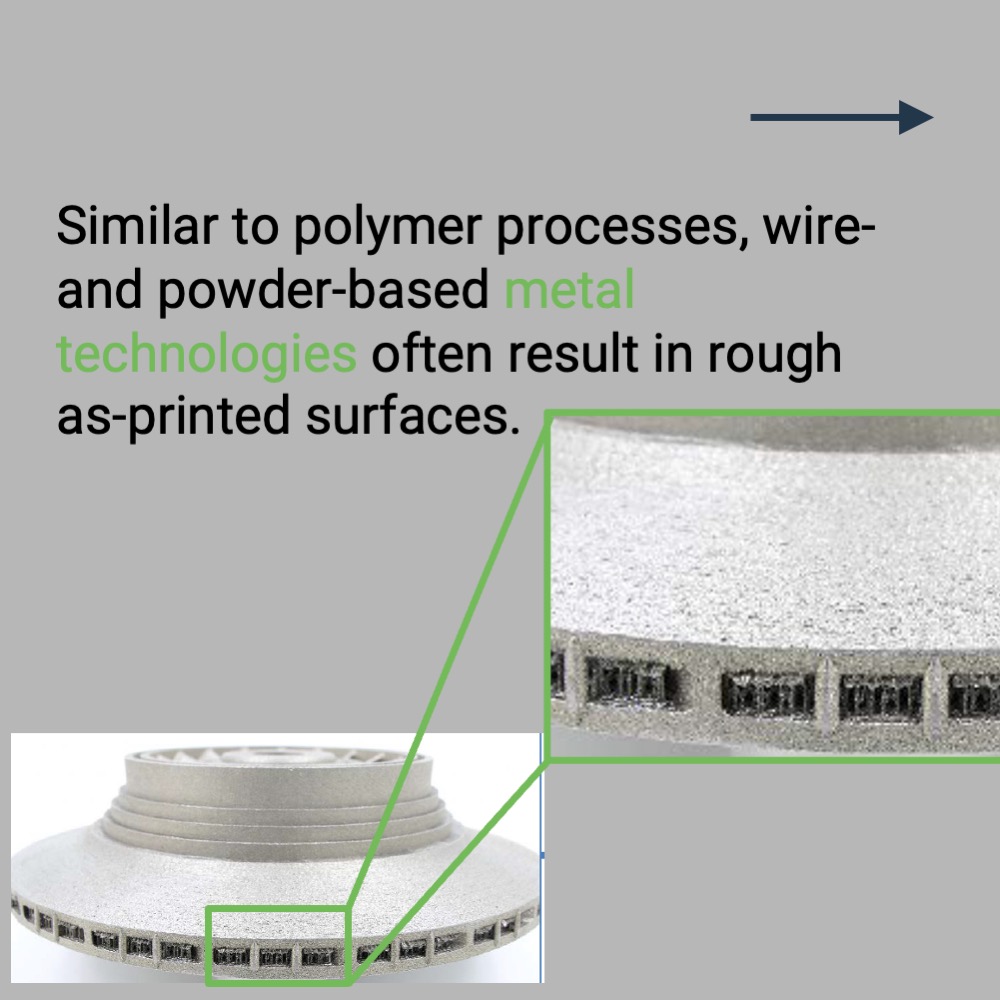

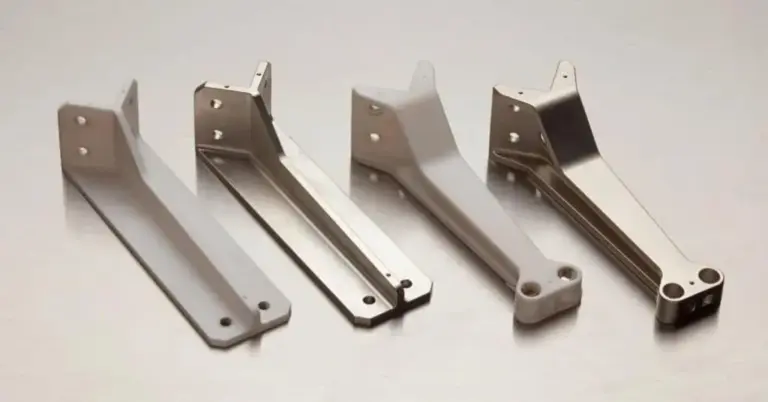

Metal wire- and powder-based technologies often leave rough surfaces, necessitating extensive post-processing to meet functional requirements.

While resin-based technologies such as VAT Polymerization (e.g., SLA and DLP) yield smoother surfaces, they are not universally applicable, especially for industrial-grade materials.

Achieving the desired surface quality in 3D printing often requires a combination of advanced technologies and post-processing techniques. While some processes inherently produce smoother surfaces, most additive manufacturing (AM) technologies require additional steps to meet industrial standards. These solutions can broadly be categorized into subtractive methods, which remove material, and additive methods, which add layers or coatings to refine the surface. Here’s an in-depth look at the available options:

Subtractive methods are commonly used to achieve smooth and uniform finishes by removing imperfections from the surface. These techniques are highly effective for both polymer and metal components:

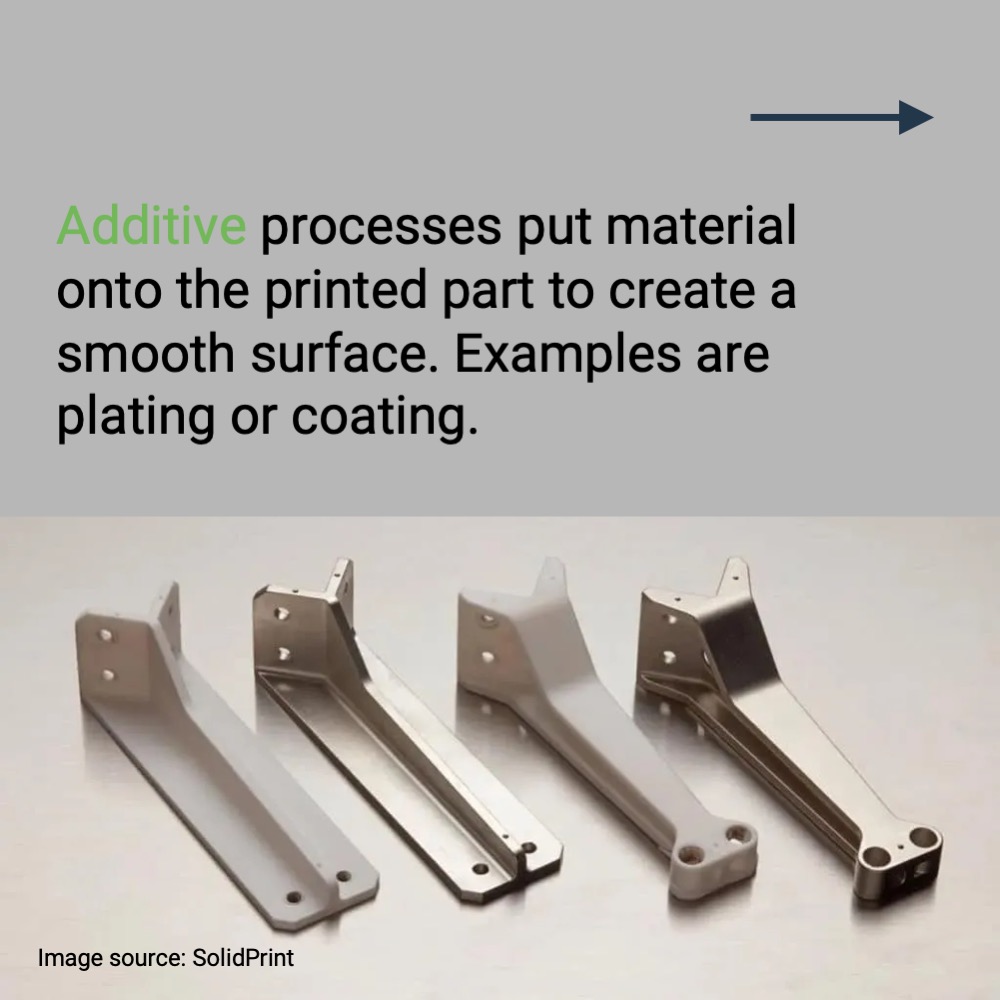

Additive methods enhance surface quality by depositing material onto the part. These techniques can also add functional properties, such as increased durability or corrosion resistance:

Emerging technologies are transforming how surface quality is improved in 3D printing:

In many cases, achieving the required surface quality involves combining multiple techniques. For example, a part may first undergo tumbling to remove major imperfections, followed by coating or plating for a polished finish. This hybrid approach is often the key to meeting both functional and aesthetic requirements.

By leveraging these solutions, manufacturers can overcome the inherent challenges of 3D printing and produce parts with the desired surface finish, ensuring both quality and performance in industrial applications.

“The newly designed training program which has been developed by AMPOWER, will provide engineers with the necessary knowledge, skills, and

AMPOWER Academy 3D printing at Deutsche Bahn Deutsche Bahn Railway Berlin, Germany 26.09.2023 Share article Frankfurt (Main) Hbf – Einfahrt

AMPOWER Academy 3D printing at Eaton Aerospace Fueling progress: How Eaton Aerospace’s dedication to 3D Printing elevated aircraft performance Eaton

Would you like to further increase your 3D Printing knowledge?

You can try out the AM Fundamentals course of the AMPOWER Academy free of charge

Understand the most important topics to get started with Additive Manufacturing