Which software do I need for 3D printing?

All Blog Articles 3D Printing Software Which software do I need for 3D Printing? Share article Navigating the world of

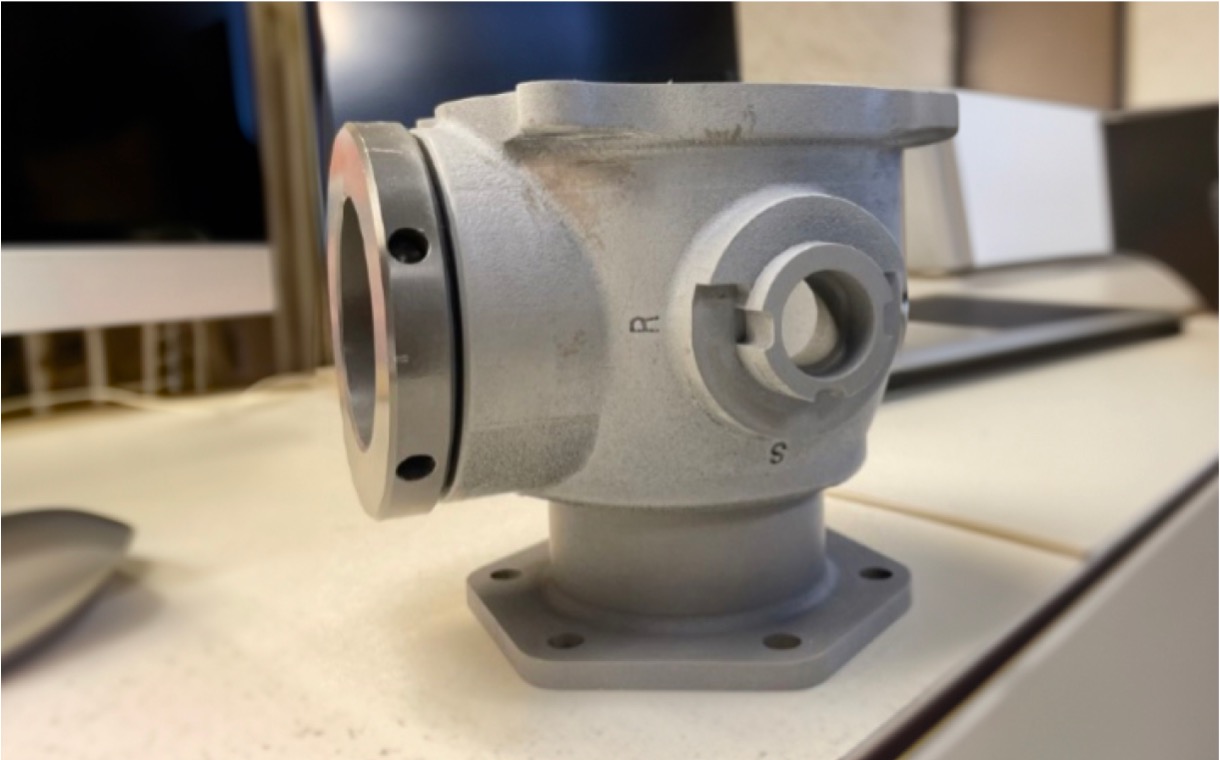

EATON AEROSPACE is a leading aerospace company with a century-long history. The company designs, manufactures, and distributes advanced systems and components for aircrafts. Their wide range of products includes hydraulic, fuel, motion control, and electrical systems for commercial and military aircraft, helicopters, UAVs and space vehicles. With a global presence and collaborations with major manufacturers, they play a vital role in shaping the future of aerospace engineering, delivering innovative solutions for improved performance and efficiency.

Since 2016, EATON AEROSPACE has been developing 3D Printing and potential applications in the Aerospace sector. In 2020, 3 qualified components were strategically launched into serial production. 3 years later today, already 23 components have been awarded with EATON customers which is an impressive growth rate considering the high hurdles of Aerospace qualification efforts. As Michael York, Director of Additive Manufacturing at Eaton Aerospace, put it: “At Eaton Aerospace we are leveraging the power of Additive Manufacturing to produce superior products and systems”.

Reduced development time thus earlier go to market

Improved part performance such as optimized packaging, reduced weight, pressure drop (hydraulics) or improved heat management

Reduced cost

Increased sustainability

With this added value centric approach, the EATON AEROSPACE Management was deeply involved and committed regarding the implementation of 3D Printing and the necessary monetary and capacity investments. This strategy also involves a long-term commitment. It was clear from the beginning, that the success in 3D Printing does not come overnight but rather must be worked on for several years and the resulting applications today prove, that EATON AEROSPACE was very successful with this long-term approach.

Besides Management, the strategy also serves engineering as a guidance and motivation. Especially by solving today’s problems with 3D Printing and increasing performance of components is what increases awareness and support in engineering. Many companies in highly regulated industries such as Aviation or Medical still struggle because of a historically risk-averse engineering department. With this value-add centric 3D Printing strategy, EATON AEROSPACE was successfully involving all relevant stakeholders from senior management, product management, quality management and engineering.

Lesson 1

Success does not come overnight and without involving

everyone along the whole value chain. A long-term value

proposition focused vision and strategy helps the company to

stay on track.

Part of a 3D Printing strategy should be the focus on strategic projects. A company-wide training needs to be established, but it is just the beginning. Soon, pilot projects need to be identified that are being driven all the way through qualification so the company can prove the successful implementation in different business units before adapting the technology broader. Qualification procedures and quality management can learn along those pilot projects which accelerates later application implementations.

Lesson 2

Establish a selection of pilot projects that solve today’s

problems early on to focus qualification efforts. This will lead

to a hockey stick of applications later on.

EATON AEROSPACE has a relatively decentralized company structure, with engineering capacities in over 41 different facilities. This bears a challenge for every company that wants to implement a new manufacturing technology such as 3D Printing. EATON AEROSPACE tackled this challenge successfully by a dedicated structure for their 3D Printing approach. In addition to a deccentrally organization, a centralized “3D Printing Center of Excellence” was established in Charlson, South Carolina, where machine technology and additional intra-company services for design and printing of parts take place.

Learning 3

Establish a center of excellence and build up internal

knowledge before qualifying external suppliers.

EATON AEROSPACE has proven that 3D Printing is here to stay in Aerospace. The technology solves today’s manufacturing problems and improves part performance which reduces cost and increases sustainability on both ends, environment and supply chain. With those three learnings, EATON AEROSPACE was able to implement 3D Printing and set the basis for a high growth within the company in the coming years.

All Blog Articles 3D Printing Software Which software do I need for 3D Printing? Share article Navigating the world of

AMPOWER Academy 3D Printing and automated design for jigs & fixtures Trinckle, Audi Sport, Deutsche Bahn Tooling, jigs & fixtures

“At AMEXCI we always strive to provide realistic, relevant, and up-to-date training content to our shareholders and customers during our

Would you like to further advance your 3D Printing success story? We learned that training a broad number of employees is key to increase the usage of 3D Printing in a company and to successfully launch new applications.

You can try out the AM Fundamentals course of the AMPOWER Academy free of charge

Understand the most important topics to get started with Additive Manufacturing

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from reCAPTCHA. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information